|

TERRABRIC MACHINE | |||||||||||||

|

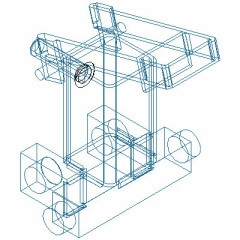

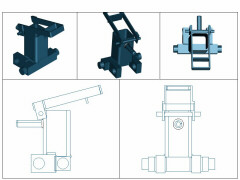

The Terrabric Machine is a ruggedly constructed soil-cement brick making machine. It is made from substantial steel sections with "axle steel" shafts. The top round shaft is case hardened carbon steel. This ensures that the equipment is able to withstand the high pressures involved in making compressed soil bricks. Design concepts are examined in detail:  Robust assemblies are tested in the field:  Parts are manufactured:  16mm steel moulding cases:  Palletted Terrabric Machines ready to ship:  The Terrabric machine can be set up to be portable (total weight 80 kg). It can be bolted to a plank, two poles or bolted down onto a concrete footing. The footing should be about 600 x 400mm in area and knee-deep. Use 4 x 12mm foundation bolts.  This Terrabric Machine is shown bolted to two 4-metre wooden poles to make it portable. The unit is most easily moved by two porters with the machine hanging upside down. The pictures in the right column of this page show a machine bolted to a concrete base. The Terrabric Machine uses a minimum amount of water to make bricks. The bricks can be made from either a mixture of soil and cement or subsoil only (depending on your requirements). This cuts out transport costs for crushed stone and sand. The finished brick size is 290 mm x 154mm x 108mm. This can make standard 4-1/2 6 and 9 inch walls. Because they are made under high pressure (about 5Mpa) the bricks are solid, smooth-surfaced with high strength and good insulation properties compared with sand-cement bricks. Production is about 100 bricks per person on the team, ie.: 6 people in the team = 600 per day. The limit is about 1200 bricks per machine per day. The most common use of the bricks is in making 6 inch walls for single story buildings. The coverage is 30 per square metre. Other sizes of Terrabrics can be made by special order. These are "Super Bricks" (a standard South African size), metric measurements (any sizes) and stock bricks. One version of the Terrabric Machine makes 2 stock bricks (229 x 110 x 75mm) at a time. This machine can also be used to mould Clay Bricks for firing. Fired clay stock bricks are frequently moulded with a method called "slop moulding". This requires a lot of work and water. Using a 2-Brick Terrabric Machine saves a lot of work, water and waste. There is less srinkage as there is less water put into the brick in the first place. Some clays are unsuitable for slop moulding because they shrink too much, but they can be used if they are pressed into shape by a 2-Brick Terrabric Machine before firing. The 2-Up version is more expensive, heavier, harder to operate correctly and produces a lower volume of bricks per day, however it makes some projects viable where no other technology will work. 2-Up Terrabric Machine making 'frogged' bricks:

|

How to use the Terrabric Machine - A visit to a real brickyard Measuring screened soil (6mm mesh) is done with a concrete wheelbarrow, typically 8 level barrows per 50kg of cement (16:1 mix). The more the clay content of the soil, the more cement is required to stabilize it.  Spread 50 kg of cement over the pile of soil. Do not try to mix the cement into the soil on this spot. It will never get evenly mixed.

Spread 50 kg of cement over the pile of soil. Do not try to mix the cement into the soil on this spot. It will never get evenly mixed.

Toss the soil and cement onto a new pile. To do this you should use an oval shaped mixing platform about 3 x 5 metres in size.

Toss the soil and cement onto a new pile. To do this you should use an oval shaped mixing platform about 3 x 5 metres in size.

Drop the shovels of soil and cement onto the top point of the new pile so they spread out by themselves. This minimizes the effort required to mix a small amount of cement with a large amount of soil.

Drop the shovels of soil and cement onto the top point of the new pile so they spread out by themselves. This minimizes the effort required to mix a small amount of cement with a large amount of soil.

If necessary, repeat the entire procedure shovelling the mix back onto the original spot. If there is already a reasonable mix of the dry ingredients, add water using a watering can (so it is added in small drops) or a perforated can. In many cases very little water is required. The final mix should be about 15% water by weight. The more clay content in the soil, the less water used (down to 10%). Notice the balls of mix forming when the mix rolls down the slope. This is normal. Mix formed into a ball with a clenched fist should stick together well, not be dry and crumbly and not be squishy-wet.

If necessary, repeat the entire procedure shovelling the mix back onto the original spot. If there is already a reasonable mix of the dry ingredients, add water using a watering can (so it is added in small drops) or a perforated can. In many cases very little water is required. The final mix should be about 15% water by weight. The more clay content in the soil, the less water used (down to 10%). Notice the balls of mix forming when the mix rolls down the slope. This is normal. Mix formed into a ball with a clenched fist should stick together well, not be dry and crumbly and not be squishy-wet.

When the soil and cement and water are properly mixed is it time to make bricks. First open the lid and move the black handle so the piston drops to the bottom of its stroke.

When the soil and cement and water are properly mixed is it time to make bricks. First open the lid and move the black handle so the piston drops to the bottom of its stroke.

It is best to have two people doing this, one holding the spade and the other pulling off just the right amount to fill the cavity.

It is best to have two people doing this, one holding the spade and the other pulling off just the right amount to fill the cavity.

Punch down the mix to create more space. The number of 'fists' to use depends on the clay content. The more clay in the soil, the more punches you make so as to add more mix.

Punch down the mix to create more space. The number of 'fists' to use depends on the clay content. The more clay in the soil, the more punches you make so as to add more mix.

Work fast. Punch 8 times for a laterite red soil with 35% clay content.

Work fast. Punch 8 times for a laterite red soil with 35% clay content.

Pre-compress the corners by jamming mix into them and wiping your hand towards the corner point. This makes stronger top corner points, especially when the water content is a little low.

Pre-compress the corners by jamming mix into them and wiping your hand towards the corner point. This makes stronger top corner points, especially when the water content is a little low.

Raise the black handle until the top round shaft hits the stop on lid and raise the red handle to release the 'top end' mechanism (the one shown in the drawings at the beginning of this page).

Raise the black handle until the top round shaft hits the stop on lid and raise the red handle to release the 'top end' mechanism (the one shown in the drawings at the beginning of this page).

Pull the handle down all the way. If it goes down easily, there is not enough mix in the cavity. The handle can cope with a 100 kg operator. In this picture two 'little guys' are working together to generate about 12-14 tons moulding pressure. When the handle is lifted after reaching the bottom, there should be a loud *click* from the base of the black handle. This indicates the moulding pressure was high.

Pull the handle down all the way. If it goes down easily, there is not enough mix in the cavity. The handle can cope with a 100 kg operator. In this picture two 'little guys' are working together to generate about 12-14 tons moulding pressure. When the handle is lifted after reaching the bottom, there should be a loud *click* from the base of the black handle. This indicates the moulding pressure was high.

To eject the brick it is wise to hold the lid open so it does not fall down as the brick emerges. Higher clay bricks are harder to eject because they stick to the sides of the cavity. If the brick is difficult to get out and emerges with a slick and torn surface, there is no cure except to reduce the water content. As a bonus this will reduce micro-cracking when curing.

To eject the brick it is wise to hold the lid open so it does not fall down as the brick emerges. Higher clay bricks are harder to eject because they stick to the sides of the cavity. If the brick is difficult to get out and emerges with a slick and torn surface, there is no cure except to reduce the water content. As a bonus this will reduce micro-cracking when curing.

Lift the brick with two flat hands. In most cases this works very well. Very sandy soils may require you to lift the brick from the ends (no kidding it works!) or from the side using two flat boards. You can also use a flat sheet of steel (about 1.6mm thick) as a tray which you place in the cavity before putting in the mix. The problem is that it has be kept very clean. You will need 3 or 4 such sheets (normally 152 x 288mm) which allows you to carry them away and carefully put the bricks on the ground and return the (cleaned) plate to the machine. The need to do this is rare but some communities only have very sandy soils. The machine will not work proplerly with sand and cement - it simply isn't sticky enough to hold together.

Lift the brick with two flat hands. In most cases this works very well. Very sandy soils may require you to lift the brick from the ends (no kidding it works!) or from the side using two flat boards. You can also use a flat sheet of steel (about 1.6mm thick) as a tray which you place in the cavity before putting in the mix. The problem is that it has be kept very clean. You will need 3 or 4 such sheets (normally 152 x 288mm) which allows you to carry them away and carefully put the bricks on the ground and return the (cleaned) plate to the machine. The need to do this is rare but some communities only have very sandy soils. The machine will not work proplerly with sand and cement - it simply isn't sticky enough to hold together.

Stack the bricks as close together as you can get them. This prevents water loss. At the end of hte day cover them with wet grass, palm fronds or plastic sheeting. Keep them wet and under wraps for as long as you can - two weeks is very good. Add water daily so the cement can be hydrated properly. Curing continues for about 28 days. They can be stacked 5 high on day 2. Build tightly packed stacks to keep the wind out and the water in. Never place fresh bricks out in the sun to 'dry'. Bricks do not 'dry', they absorb water and the cement keeps it in a process called 'curing'. A scientific curing regimen allows you to reduce the cement content (to about 4%) and still get good strong bricks.

Stack the bricks as close together as you can get them. This prevents water loss. At the end of hte day cover them with wet grass, palm fronds or plastic sheeting. Keep them wet and under wraps for as long as you can - two weeks is very good. Add water daily so the cement can be hydrated properly. Curing continues for about 28 days. They can be stacked 5 high on day 2. Build tightly packed stacks to keep the wind out and the water in. Never place fresh bricks out in the sun to 'dry'. Bricks do not 'dry', they absorb water and the cement keeps it in a process called 'curing'. A scientific curing regimen allows you to reduce the cement content (to about 4%) and still get good strong bricks.

High strength soil-cement bricks (15% cement) are used for foundations.

High strength soil-cement bricks (15% cement) are used for foundations.

|

|||||||||||||

| << Back | ||||||||||||||