|

TWO-OPERATOR MANUAL FLOOR COOKING OIL PRESS | |||||||

|

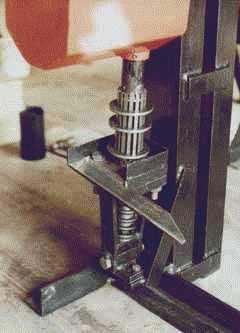

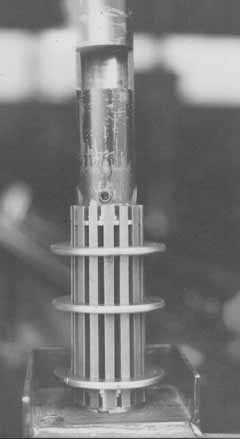

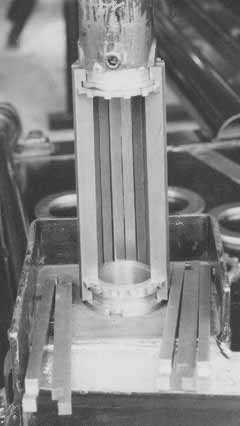

The Cooking Oil Press is used to squeeze oil out of oil-bearings seeds and nuts. The press is manually operated and can be ordered with different cage bar spacing to suit different sizes and types of seed. The smaller or softer the seed, the smaller the gap between the bars in the cage. Capacity The throughput of the press is nominally 100 Kg per day. This represents a "cycle time" of 7 to 8 seconds. If it is operated at about 5 seconds per stroke the thoughput will be up to 130 Kg. When you speed up, the recovery rate of the oil drops a bit, but it produces more total oil per day. This can make a difference to you is you are holding a great deal of seed in storage and wish to press it within a certain time period - say, a single season. If 100 Kg of hybrid sunflower seed is pressed in a day, you can expect 25 to 33 litres of raw oil to be pressed out. This has to be settled in buckets, drums or other containers for a week or more. This will yield about 18 to 25 litres of pure, cold pressed oil. Economics In the economics of the production, you will find that the capital cost of holding seed for a long time is sometimes more important than maximizing oil recovery. This calculation varies from country to country so examing your proposed project in light of the prevailing circumstances. Generally speaking, the value of the seed purchased equals the value of the oil on the local market. The residue (called seed cake) is a very valuable dairy cattle feed supplement worth about 2/3 of the price of the seed per kg. 1000 kg of seed is purchased for about $250, or grown for half of that. The 250-300 litres of oil pressed is worth $275-325 if sold as "hot-pressed" (though in fact it is not). The cake left over, about 700 Kg, is worth another $130. This shows that the cake is a very important part of the economics and it must be sold as feed to realize a reasonable return on the investment and labour. Cold pressed oil is worth a lot more than hot pressed but you might not find a local market for it. Using the press The hopper is loaded with about 7.5 Kg of seed. The handle is raised to be vertical. The seed feeds into the cylinder. The handle is lowered to about waist level where it will stop falling. Press down firmly and rapidly on the handle until it is about 250mm off the floor. This loads a charge of seed into the cage. Pause very briefly by taking some weight off the handle and then continuing pressing it slowly down to the floor. It is during this last part of the action that the oil is squeezed out. If you press slowly the whole time, the oil will back up into the seed hopper and the wet seed will not fall into the cylinder without being assisted by hand. The seed feeds well if the motion is correct. The press is operated by two or three people. The handle presses down to the ground on one side and then is passed over the top to another operator on the other side. This gives them a rest as they take turns pressing the handle down. The resistance of the handle can be set by shimming the automatic choke plug. Whether operated fast or slow, the pressure inside the cage remains the same at all times. The third person can stand in the centre and help pass the handle back and forth. This reduces the walking by both operators to almost nil. They can continue pressing for several hours without needing a rest. Choosing seeds The oil content has to be comparatively high - about 35% or more - to work effectively. Suitable seeds are sunflower, sesame, caster and a few others. Not suitable are cotton seed, soya beans and unhusked neem seeds. The most common seed to be pressed on a small scale is sunflower. There are more than 100 varieties of sunflower and their oil content varies from one to another so be careful you are planting or buying a seed with a high oil content. A good open pollinated variety is Record which has 38-43% oil. Good hybrid varieties are PNR7204, PNR7395, or PNR7225 for low rainfall areas, less then 600mm (these are Pioneer varieties) . All of them are in the 47-49% range. SO323 (Sofala) has had the highest output per kg of seed pressed (34.5% reported), though it is not a heavy yielding variety per hectare. There are many others. Technical information The fully hardened piston is self-lubricating. The patented choke ring above the cage breaks up the seed while heating it with mechanical energy. The choke ring can be changed for different amounts of choking to work the seed properly. The cage can be dismantled without anything more than an iron bar which is used to lift the 3 rings. The cage bars separate easily for cleaning. This is a unique feature of this press. No spanners are required for normal maintenance. A sharpened rod is good for digging out hardened cake if it is left for too long without being used and the operator forgot to clean it. Having only 3 moving parts ensures a long service life. The main shaft is mounted on ball bearings. The handle is 1.8 metres long. Piston Dia............................40mm Stroke.................................105mm Operating psi.......................up to 1250 psi Spring sizes are 11mm for new seed, 10mm for old seed (1-2 yrs). Cooking Oil Press Assembly Instructions here.

|

Sunflower seed and Cooking Oil Press: Oil drain and expeller cage:  Expeller cage:  Cutaway of expeller cage:  |

|||||||

| << Back | ||||||||