|

TWO-OPERATOR MANUAL MARULA NUT OIL PRESS | |

|

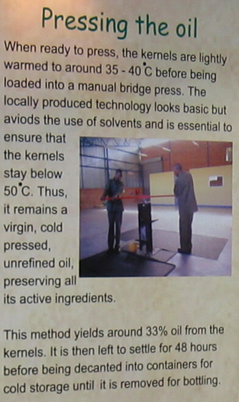

The Marula tree is a drought resistant stalwart of the 'veldt' seen everywhere, rarely cut for fuel because of its fruit and nut products. Famous for getting elephants tipsy, the marula fruit ferments naturally on the tree. It is collected over a vast area in Africa for making wine during a 'maganu season' from January to May. Maganu is the name Swaziland gives to the 'brew' though it is so easy to make, there is no brewing required. What is left over is a large pile of marula nuts. These are often tossed into a wet pile under a tree - ideal conditions for the growth of Fusareum Roseum mould, a potent source of Aflatoxin. Correctly dried immediately after the maganu is made, they are a nutritious delicacy. This means drying them as quickly as possible in direct sunlight, spread in a thin layer in a plastic sheet or mats. The idea is to prevent a warm wet nut from getting indirect sunlight. Once dried they are stable for quite some time. In some communities these are stored to use if they run low on food. The food in the nut is two or three soft beige kernels containing a valuable cosmetic oil, though they taste so good most people never find out. They are a delicious snack, provided you are willing to go to the trouble of opening them. The properties of the oil have been well known in Africa for centuries. It is used traditionally to prevent and treat stretch marks on pregnant women. It has remarkable properties as a 'wrinkle cream'. It is renowned for healing scar tissue. Modern analysis reveals a high level of Vitamin E and Folic Acid. It is the most stable known natural vegetable oil. It can be made into a natural soap (45% oil) and body lotion. At the behest of Her Royal Highness, the Indlovukazi, a project "Swazi Indigenous Products" was started to make use of traditional resources in a bid to create rural employment. The Marula Nut Oil Press was developed by New Dawn Engineering to express the oil. It is a difficult nut to press containing little fibre, and it is a spongy, soft nut with a relatively high amount of oil. The seed must be pressed gently at first and as the oil level drops, the pressure can be increased. This is most effectively accomplished by means of a hand operated press. It was discovered that the oil content varies in the region, with the drier places having a higher oil content. As the seed cake is compressed it gets quite hard and towards the end of the cycle the pressure is raised significantly. As a result of this process, there is no need to cycle the seed cake through the machine several times (usually three) as has been necessary with other equipment. Due to the slightly lower oil content of the seeds in Swaziland, the yield of oil is 33% of the mass of the nuts. In Botswana 40% has been achieved. Published reports on oil content show that the level in the Kruger Park area are similar to Swaziland's. The official launch of the project took place on 27th July 2005 at the Job Summit. The Summit was launching the One Billion Emalangeni Job Creation Fund (about $180,000,000). This high profile launch noted that the use of indigenous African natural products with a high value added can create significant wealth in rural areas provided the raw materials are not exported at low value. Each Marula Nut Press creates 30 to 40 jobs. The work of taking out the kernels is the main part of the work and it is done at home by individuals or families whenever they have time. This extremely valuable income because it is cash earned for zero expense. The seeds are collected by the project and payment made on the spot according to the weight. About 2/3 of the value of the oil is wages paid to the nut crackers. Capacity The throughput of the press is nominally 33 Kg per day. This represents a "cycle time" of 15 minutes. If the seed is from Swaziland you can expect 11 to 12 litres of raw oil to be pressed out. It has to be settled for 48 hours in buckets, drums or other containers. This will yield a pure, cold pressed marula oil. Technical information It is a screw-type press that processes one batch at a time. The huge piston is threaded on top and mounted in a large bronze nut. The piston travels down into the cage compressing the kernels. When it presses out the air, resistance increases and the oil starts to flow. When the oil is finally pressed out, the bottom sliding door is pressed to the opposite side and the seed cake is expelled downwards. It emerges horizontally from a tube at the bottom of the press where it can be collected in a sterile container. It can be sold as a snack. The cage can be removed for cleaning by removing its top clamp. Piston Dia............................80mm Stroke...................................325mm Operating pressure...........up to 750 psi |

Marula Nut Oil Press: Weighing nut kernels:  Oil and skin cream:  Wonderful soap!  Swazi Indigenous Products poster:  Their process in a nutshell:  Crispin building the second prototype:  Moving parts aligned before welding:  The handle fits over the squared top of the shaft:  Oil pressing in process:  His Royal Highness the Ngwenyama of Swaziland inspecting the newest marula nut oil press at the launching of the National Job Summit, 28 July 2005. He commented that $50 was a very good price to pay for the creation of a job. The first press created 28 rural jobs and 12 in the processing plant at Mpaka.  Photo: Sonto Bhembe |

|

| << Back | ||